The idea of a circular economy and closing the materials loop has been an aspirational goal for decades. But circularity as an afterthought has never really worked. We are finally starting to see products that are designed from the ground up to utilize materials that are already circulating in the economy while producing zero additional waste in the manufacturing process. An intriguing example of a circular product is the Circular Memory Jacket from Dhana, made with used clothing materials. Our life-cycle assessments (LCAs) show that these circular jackets have just 1/3 of the carbon footprint of a similar non-circular jacket and negligible water footprint – all from using 100% repurposed materials.

Systems modeled in this study

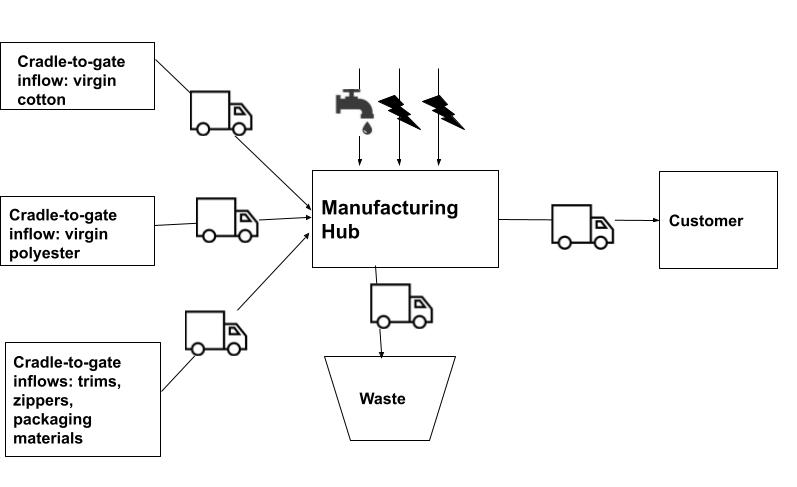

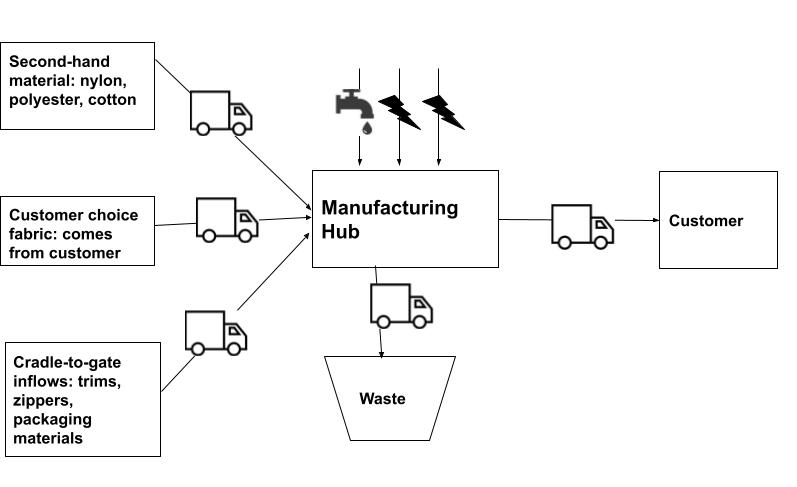

The system boundary for the LCAs is cradle to retail, starting from resource extraction and ending with the delivery of the jackets to customers. We use LCAs to compare the environmental impacts of a conventional non-circular jacket with a circular jacket from Dhana.

The functional unit for the LCAs is one circular or non-circular jacket. The LCAs consider three life-cycle impact categories:

- Carbon/GHG Emissions (climate change), kg CO2e/garment: Greenhouse gas (GHG) emissions – includes CO2, methane and nitrous oxide.

- Energy, MJ/garment: Primary energy use – includes combusted and feedstock energy.

- Water, L/garment: Water consumption – includes surface and groundwater used.

LCA tools and methodology

We used our carbon modeling tool, CarbonScope, to conduct the LCAs in this study. The life-cycle inventory database underlying the analysis is CarbonScopeData. The analysis was done using our Rapid Carbon Footprinting (RCF) methodology. An important part of this study is the modeling of recycled/repurposed materials in LCAs, which was done using the using the “recycled content” method.

Results and conclusion

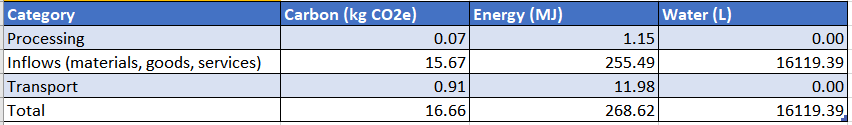

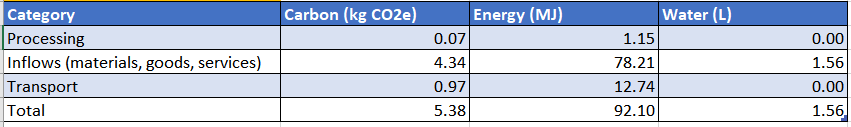

The life cycle impact assessment results below show that the circular jacket generates less than a third of the GHG emissions that a generic, non-circular jacket would generate from the production and transport. The emissions are dominated by the materials used to make the jackets, including cotton and polyester. Final processing (i.e., garment manufacture) and transport (both incoming and outgoing) are minor contributors.

The water footprint of a circular jacket is negligible compared to the substantial water consumption in the life cycle of a non-circular jacket, largely due to the water required to produce the virgin cotton used in the non-circular jacket.

The results clearly show the significant environmental advantages that can be achieved by reusing materials that are already circulating in the economy as opposed to using virgin materials. We have seen similar results in the case of other LCAs of outerwear. The economics and logistics of recycling may be challenging in general, but the clothing sector is one where circular production looks like a practical solution that can dramatically lower environmental footprints.

——

The customer featured in this case study, Dhana Inc., is headquartered in Sausalito, California. Dhana is a certified B Corp and a pioneer in circular fashion whose mission is to connect people and planet through the medium of fashion.